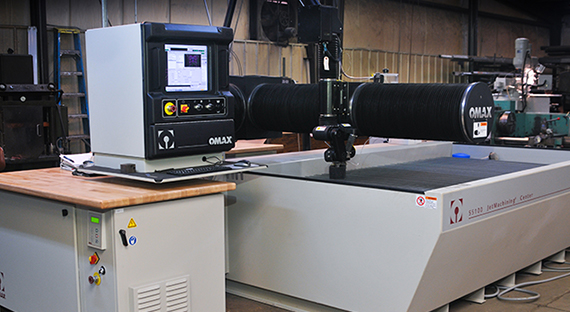

B & S Machine Tool provides complex cutting of virtually any material with its state-of-the-art abrasive waterjet cutting system. Complex flat parts with standard tolerances of +/- .003” can be produced from metal, plastic, glass, ceramics, stone, composites, extremely hard, reflective, and non-conductive materials.

Part geometry can be provided directly from CAD drawings, computer generated files, or scanned images.

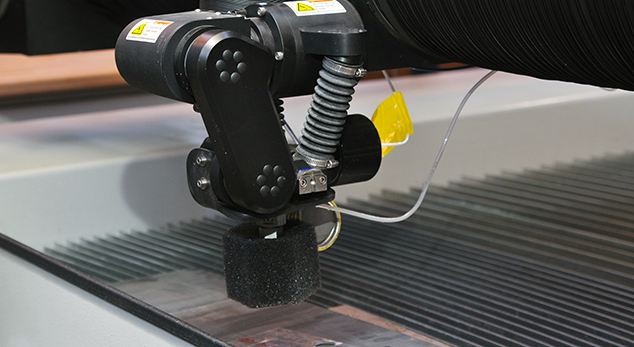

The B & S Machine Tool system includes an articulating cutting nozzle which automatically compensates for taper to provide a smooth, vertical edge, with no burrs, stresses, or heat-affected areas.

In addition, our system configuration includes dual 55,000-psi pumps for a 35% cutting speed advantage over standard waterjets.

| • | Maximum material thickness: | 7” |

| • | Cutting part size: | 55” x 100” |

| • | Maximum sheet/plate size: | 60” x 120” |

Contact B & S Machine Tool today to request a quote and learn how our Aiken, South Carolina production plant can support your business.